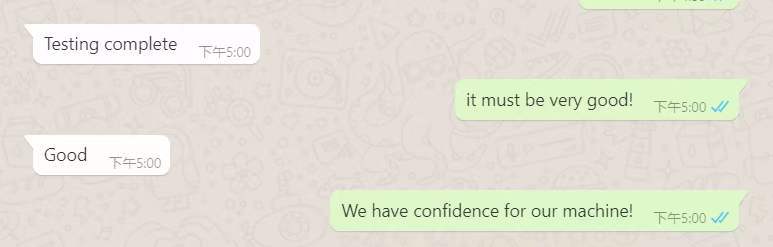

The screw air compressor arrives, and the customer's inspection is completed

- Share

- publisher

- Michael Xu

- Issue Time

- Oct 20,2021

Summary

The screw air compressor arrives, and the customer's inspection is completed

☆ Daily inspection and commissioning

1. Frequently observe the pressure displayed on the pressure gauge and the exhaust pressure displayed on the instrument panel. When the pressure difference exceeds

When it exceeds 0.12Mpa, replace the filter element of the oil fine separator in time.

1. If the fuel consumption increases suddenly during the operation of the machine, check whether the throttle hole of the one-way valve behind the oil return pipe is blocked.

Stuffed.

2. The safety valve should be inspected regularly. The inspection method is to gently pull the top of the safety valve when the compressor is working at full load.

If the safety valve can vent outward at this time, it is regarded as normal.

3. Check whether the oil level in the oil-gas barrel is between the two engraved lines of the oil level gauge. After running, it should be stopped for 10 minutes.

conduct. At this time, the oil flowing in the system has basically returned to the oil and gas barrel. The oil level during operation may be higher than the oil level during shutdown

Slightly lower. If it is not enough, please add it in time.

4. Although there is phase sequence protection, the direction of the host should be checked. The method is 2 seconds after pressing the start button,

Press the emergency stop button to confirm that the direction of the main engine is consistent with the direction of the arrow on the end face of the nose.

5. When starting up, observe whether the pressure and temperature rise normally, and whether the display shows abnormality. If there is

If an abnormality is displayed, immediately press the "emergency stop button" to stop and check.

6. Check whether the machine can be loaded normally, if there is abnormal sound, abnormal vibration or oil leakage, etc.

Like, immediately press the "emergency stop button" to stop the inspection.

7. Check whether the exhaust temperature is kept below 95℃.

8. Before each start-up, slightly open the drain ball valve under the oil and gas barrel to remove the condensation in the oil and gas barrel.

Water, once you see oil flowing out, quickly close the valve. For compressors in severe cold environments, lubrication should be ensured

The oil will not condense.

9. When replenishing lubricating oil, you should confirm that there is no pressure in the system before opening the oil filler cap. Mixed-use is strictly prohibited

Lubricants of different brands may increase fuel consumption and even cause serious consequences for the machine head to jam.

10. Rotate the air compressor by hand for several revolutions. It should be free to move. If there is jamming, check the cause.

11. To ensure safety, always check and record the exhaust pressure, ambient temperature, and exhaust temperature during operation

Parameters such as oil level and oil level.

12. During operation, the oil circuit system is filled with high-temperature and high-pressure liquid. Do not loosen the oil circuit or carry out other dangers.

operate. If there is an abnormal sound, abnormal vibration, etc., immediately press the "emergency button" to stop the machine.

☆ Treatment methods for long-term downtime

When shutting down for a long time, the following methods should be strictly followed, especially in areas where the temperature is lower than 0°C.

1. Processing after shutdown for more than 1 month

2) Wrap the controller, distribution box, and other electrical equipment with plastic paper or oil paper to prevent moisture intrusion.

3) Drain the water in the oil cooler and aftercooler completely to avoid freezing and cracking of the oil cooler.

4) If there is any malfunction, it should be eliminated first for future use.

5) After two or three days, drain the condensed water in the oil and gas barrel, oil cooler, and aftercooler.

2. Dealing with the shutdown for more than 3 months

In addition to the above procedures, the following treatments are also required

1) Close all openings to prevent moisture and dust from entering.

2) Change the lubricating oil before stopping use, run for 30 minutes, and drain the oil and gas barrel and oil cooler after two or three days

Of condensate.

3) Drain the condensed water completely.

4) As far as possible, move the machine to a place with less dust and dry air.

3. Restart the program

1) Remove all plastic paper or greased paper from the air compressor.

2) Measure the insulation resistance of the motor, which should be above 1 megohm.

3) Other procedures are as described in the trial run.