Reciprocating air compressor

- Share

- publisher

- Michael Xu

- Issue Time

- Nov 29,2021

Summary

Reciprocating air compressor

Reciprocating air compressor

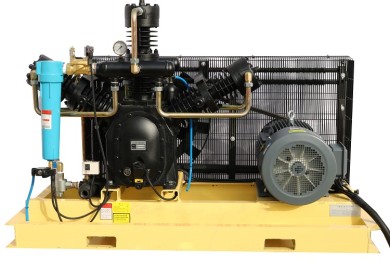

Reciprocating air compressor is a machine that uses the reciprocating motion of piston or diaphragm in the cylinder to change the chamber volume and pump in and out air.

Jinjing reciprocating air compressors include low-pressure piston air compressor, low-pressure oil-free piston air compressor, special air compressor for bottle blowing machine, medium pressure booster, medium pressure piston laser cutting combination machine and DG series piston high-pressure air compressor.

After the motor is started, it drives the crankshaft to rotate. Through the transmission of the connecting rod, the piston moves back and forth, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston will change periodically. When the piston starts to move from the cylinder head, the working volume in the cylinder increases gradually. At this time, the gas pushes the inlet valve along the inlet pipe and enters the cylinder until the working volume reaches the maximum, and the inlet valve is closed; When the piston moves in the opposite direction, the working volume in the cylinder decreases and the gas pressure increases. When the pressure in the cylinder reaches and slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder until the piston moves to the limit position, and the exhaust valve closes. When the piston moves in the opposite direction again, the above process repeats. In short, the crankshaft rotates once, the piston reciprocates once, and the process of intake, compression and exhaust is realized successively in the cylinder, that is, a working cycle is completed.

Jinjing has designed reciprocating single stage air compressors and two stage air compressors to last a lifetime — Thanks to quick, easy maintenance with renewable components. Easy access to the pump components in our reciprocating compressors allows for routine maintenance and replacement of parts like the individually cast cylinders, the piston wear-sleeves, and the 15,000-hour bearings. Easy reciprocating air compressor component replacement lets you amortize your initial capital cost over a much longer equipment life span, for a superior payback on your investment.

30Bar Booster Air Compressor Booster High Pressure Compressor

3MPa Middle Pressure Air Compressor Heavy Duty Air-Compressors

Combined 30bar Piston Air Compressor with Tank and Dryer for Laser

250bar Air-Compressors Electric 300bar High Pressure Air Compressor Kompresor