Jinjing Air Compressor--High Pressure Screw Air Compressor

- Share

- publisher

- Michael Xu

- Issue Time

- Jan 5,2022

Summary

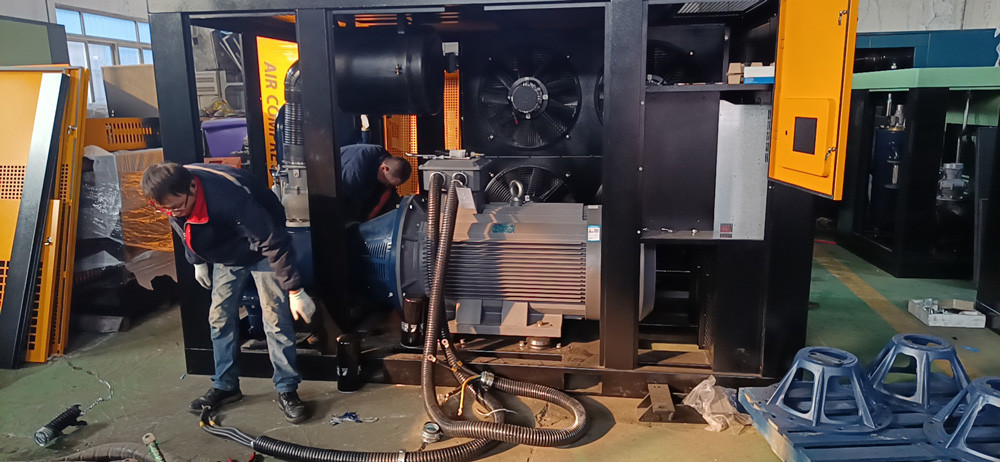

Jinjing Air Compressor--High Pressure Screw Air Compressor

Jinjing focuses on the research and development of [air compression system], and provides one-stop service of complete machine sales, parts, maintenance, and repair. High pressure screw air compressor.

Jin Jing shares with you what are the measures to prevent the oil core of the air compressor from burning?

1. Air compressors that have been out of service for a period of time, or when the temperature is low in winter, before starting the machine again, add a small amount of lubricating oil to the main engine so that there is lubricating oil and cooling when the main engine starts.

2. In daily operation, pay attention to the exhaust temperature of the air compressor. If the exhaust temperature of the machine is too high for a long time, find out the cause of the high temperature and solve the problem. Let the air compressor run under normal exhaust temperature, high-pressure screw machine manufacturers,

Avoid the long-term high temperature of the machine, which will cause the failure of the oil circuit system and cause the fire. High pressure screw machine

3. Electrostatic discharge and open flame will destroy the oil separation core. Check whether the grounding of the air compressor is normal, whether the oil and gas barrel is connected to the ground of the machine, and when installing the oil separator, pay attention to whether there is any foreign matter on the surface of the oil and gas barrel that is in contact with the asbestos pad. Such as rusty planes,

There is a plane coated with sealant, or other foreign matter affects the continuity with the oil component grounding.

4. Check whether there are fibers, foams or other materials in the electric control box, and prevent the electric arc generated by the various parts in the electric control box from igniting these materials and the high-pressure screw air compressor, which may cause fire and destroy the machine.

5. The high temperature problem of the air compressor with temperature control valve should follow the principle of the problem. The temperature control valve should be replaced if it is broken. Do not short-circuit the temperature control valve at will. High pressure screw machine

6. Oil-injected rotary air compressors generally do not have the problem of carbon deposits due to low exhaust temperature. High-pressure screw compressors, but as circulating oil, should have a good effect to ensure a certain life. For oil-injected rotary air compressors, special

Oil, or circulating oil with good demulsification. The volatility of the agent should be low enough at the general compressor temperature to keep the lubricating oil until the oil change time.