Overview of screw-type air compressors

- Share

- publisher

- Leo Wang

- Issue Time

- Jan 1,2023

Summary

Overview of screw-type air compressors

Among modern industrial air compressors, screw type air compressor technology is the most widely used. Its main features: stability, reliability, durability and easy

maintenance. It is the main source of power for many factories in the production process. Its durability is suitable for many harsh factory environments. Without it companies around the world would experience increased costs and efficiency problems.

Overview of screw-type air compressors

Screw air compressors

Overview of screw-type air compressors

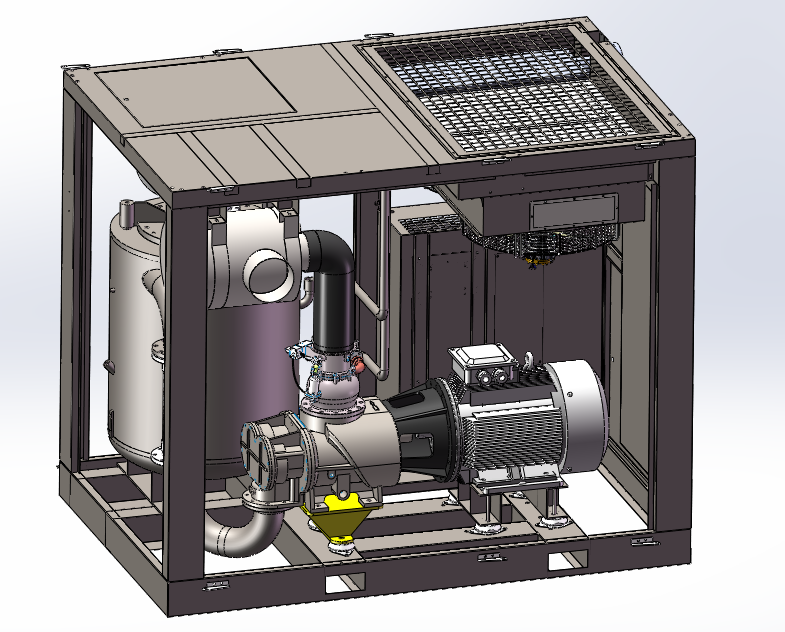

Among modern industrial air compressors, screw type air compressor technology is the most widely used. Its main features: stability, reliability, durability and easy maintenance. It is the main source of power for many factories in the production process. Its durability is suitable for many harsh factory environments. Without it companies around the world would experience increased costs and efficiency problems.

Working Principle of Screw Air Compressor

A screw compressor uses a rotating screw to compress air. Inside the compressor there is a set of rotors, usually we call them the positive and negative rotors. Driven by a motor, the rotors begin to rotate and the air is confined between them. The positive rotor has a convex blade and the negative rotor has a concave chamber; according to their characteristics, they compress the air after meshing together and rotating at high speed. The positive rotor has fewer blades than the negative rotor, so it rotates faster under the motor and drives the negative rotor more efficiently. This results in more efficient compression of the air. Unlike the piston compressor principle, the screw compressor does not have a control valve. Therefore, screw compressors are more stable and less noisy at high speeds. The structure of the screw compressor is more space-saving.

Advantages of screw air compressors.

1.Continuous operation: according to the characteristics of the rotor is able to continuously pressurize the air without the need to shut down the operation of it.

2.Stability: The rotor is processed with high coaxial fineness, and the centrifugal force is small, so the air compressor runs smoothly during operation, with less equipment jitter and noise.

3.Easy maintenance: The air compressor has fewer rotating contact surfaces, and wear and damage are minimized. Therefore, the maintenance interval and repair cost are very low. The simple structure of screw air compressor facilitates quick maintenance and inspection.

4.Applicability: Screw compressors can work continuously under very harsh conditions. And they have high air pressure rates for smooth operation in extreme temperatures. This means they can be adapted to any engineering environment.

Screw type air compressor classification: oil-filled and oil-free type

1、Oil-filled screw type air compressor.

Oil-filled type uses lubricant in the compression chamber to cool and lubricate the compressor elements. The lubricant helps to form a seal and also has a good noise reduction effect. Oil-lubricated compressors are reliable, durable and efficient, suitable for a variety of production processes and provide a constant flow of powered gas for a variety of plants. Downstream equipment such as oil filters and dryers remove any oil from the final product, producing a clean compressed air stream suitable for construction work, waste management, quarrying, recycling and many other applications. jinjing air compressor designs and manufactures a full range of lubricated screw air compressors from 2 to 250 kW, with airflows from 0.24 to 47 m3/min and pressures from 5 to 13 bar.

2、Oil-free screw type air compressor.

Oil-free compressors do not use any lubricant in the compression chamber, effectively eliminating the risk of contamination. When a plant's production process requires high-purity compressed air, even the smallest amount of contaminants in the compressed air can lead to interruptions in the production process and even damage to the final product, oil-free models can give you peace of mind. For contaminant-free compressed air, trust oil-free screw air compressors. jinjing air compressors use low and high pressure dry screw air compressors individually driven by variable speed motors to deliver unmatched levels of energy efficiency. The breakthrough design is compact, space-saving, and does not compromise performance. In fact, its footprint is 37% smaller than that of a conventional two-stage oil-free compressor! Other products in our oil-free line include water-injected screw compressors, which provide customers with 100% air purity. In this model, premium water is used to lubricate, cool and seal the compressor in place of oil. By completely removing oil from the process, you can guarantee a dry air output ideal for a range of demanding industries, such as chemical, pharmaceutical and food and beverage. For applications where compressed air comes into direct contact with the product, the jinjing air compressor series is an excellent choice.